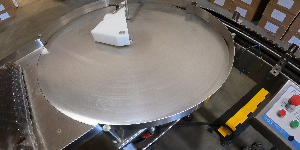

Filamatic Syn-a-8-2 Semi-Automatic Liquid Filling Machine

Filamatic Syn-a-8-2 Semi-Automatic Liquid Filling Machine

$120,000

or

Call (612) 913-6373

Description

This system is in excellent condition, as it was leased by a company that purchased it for a contract that never came through.

Overview

- Fill accuracy of ±/- 1% or better

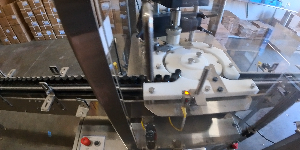

- Horizontal bottle centering system

- Programmable controller

- Scalable filling stations

- Fallen bottle sensor at infeed

- Dispenses free flowing to high viscosity liquids

- Design allows you to expand from 2 to 20 nozzles as production demands increase

- Optional multi-stroke system extends range beyond one Liter

Description

- The Synchromat in-line filling system provides automated, high-speed liquid filling and integrated handling for small to large-sized containers, all within a heavy-duty stainless-steel frame.

- Consisting of automated, diving nozzles with optional bottom-up servomotor driven dispensing, multiple indexing technologies to suit varying container profiles.

- Highly- expandable pump drive system, this turnkey filling system can grow with the demand for your product.

- With the expandable drive-bar assembly, the Synchromat is capable of single-stroke filling of containers up to 1100 mL (37 oz) in size.

- At optimal conditions, total output rates as high as 200 bottles per minute are possible, with pump quantities expandable to drive upwards of 20 simultaneous filling stations.

- Thanks to the scalable nature of the drive system, a unit that begins with two pump stations could one day be retrofitted to run upwards of ten or even 20 stations.

- A multi-stroke operation mode makes filling possible for even larger container sizes without additional operator intervention thanks to the programmable on-board controller.

- For maximum user-friendliness, a digital HMI touchscreen provides easy access to all functions for troubleshooting, maintenance, and observation.

- A range of piston-cylinder pump configurations and sizes allow for accurate, repeatable filling across a variety of product types.

- Multiple nozzle designs to select from assure minimal dripping, stringing, or foaming during the dispensing process, while maximizing your overall product output.

Specifications

| Condition | Used |

| Stock Number | 00116 |